We always take reliability and safety as the primary design goals. Each valve is designed strictly in accordance with international standards (such as API, ASME, ISO, etc.) to ensure long-term stable operation under harsh working conditions such as high pressure, high temperature, and corrosive media.

Our design begins with an understanding of actual working conditions. Different media, temperatures, pressures and operating frequencies will affect the selection and structure of valves. We provide customized solutions based on the needs of engineering projects, including material selection, sealing structure optimization and drive mode matching.

Sealing performance is the focus of the design. We select soft seal or metal seal structure according to different working conditions, and use precision processing and testing methods to ensure zero leakage or meet the most stringent leakage level in the industry.

The valve structure adopts modular design, which is convenient for maintenance and parts replacement, reducing the maintenance cost of customers. The design fully considers the convenience of operation and long-term maintainability.

The valve structure adopts modular design, which is convenient for maintenance and parts replacement, reducing the maintenance cost of customers. The design fully considers the convenience of operation and long-term maintainability.

For applications involving flammable, toxic or high-risk media, our valve designs comply with fire protection standards such as API 607 and fugitive emission standards such as ISO 15848 to ensure equipment and environmental safety.

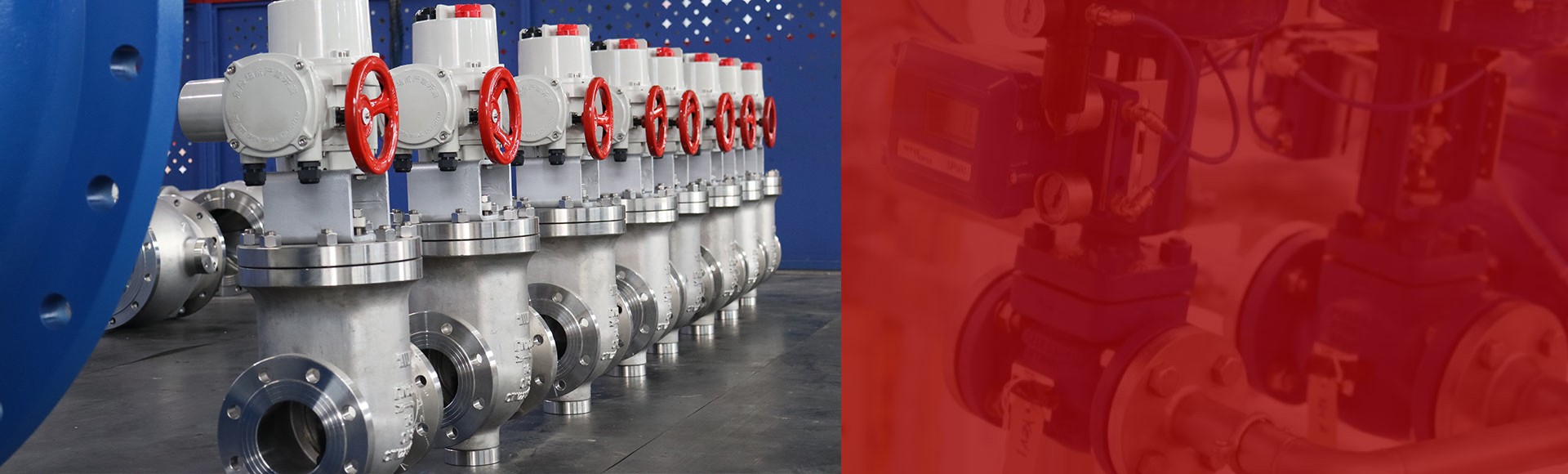

Whether manual, pneumatic, electric or hydraulic actuators, our valve designs can be seamlessly matched to achieve precise control and remote automation needs.

We continue to collect customer feedback, track project operation data, and continuously optimize product design through digital simulation, FMEA analysis and other methods to improve product performance and user experience.