WELKIN specializes in industrial valve solutions that drive efficiency and reliability in phosphate processing plants. The harsh chemical environments in these facilities demand valves that can withstand corrosion, abrasion, and high pressures. In this article, we explore the essential considerations for choosing the right valves, drawing on our expertise to provide durable, high-performance options.

Understanding Valve Purposes and Fluid Challenges

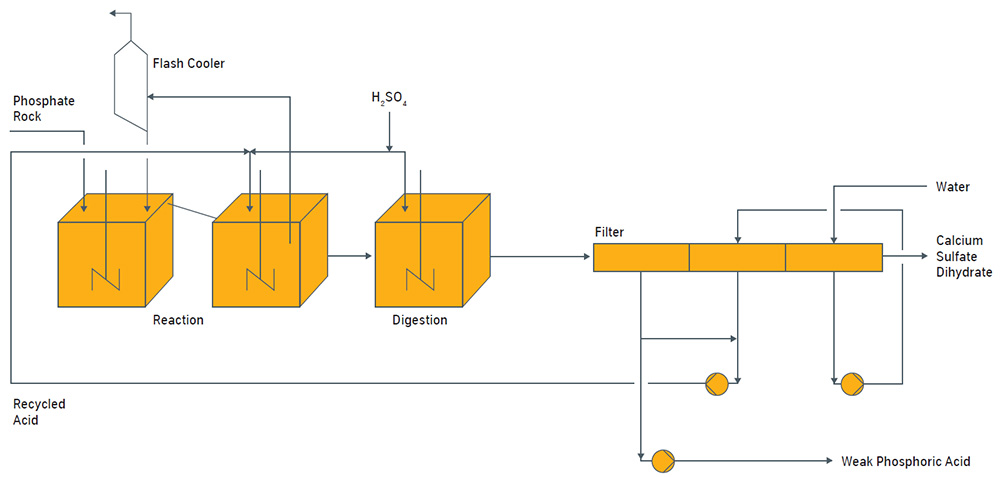

Valves in phosphate plants serve critical functions like flow control, pressure regulation, and isolation. WELKIN's lineup includes plug valves, ball valves, gate valves, butterfly valves, and diaphragm valves, each optimized for specific tasks in abrasive settings.

Phosphate slurries and acids, such as phosphoric acid with pH levels as low as 1-2, are notoriously corrosive and viscous, with high particle content that can erode standard materials. That's why WELKIN valves are built from robust options like 316L stainless steel (for moderate corrosion in wet-process phosphoric acid), 904L / Hastelloy C-276 (for severe acidic environments), or titanium Grade 2 linings, ensuring they handle extreme conditions without failure. These materials offer corrosion rates below 0.1 mm/year in 50-70% phosphoric acid solutions.

Operational and Economic Factors

Phosphate operations often involve intense pressures up to 10-15 bar in digestion reactors and elevated temperatures of 80-100°C in filtration processes, with variable flows laden with solids like gypsum. Our valves are designed to manage these demands, minimizing erosion and delivering reliable performance to keep your systems running smoothly. For example, in slurry transport lines, our ceramic-lined gate valves prevent wear from abrasive particles at flow rates of 5-10 m/s.

We also emphasize economic balance—initial investment, ongoing efficiency, and maintenance costs. WELKIN's durable designs, compliant with NACE MR0175 standards for corrosion resistance in sour service, extend service life, cutting downtime and expenses in demanding environments.

Materials are selected for superior resistance to chemical attacks and wear, adhering to strict safety and environmental regulations in phosphate processing, including ISO 9001 quality standards.

When evaluating valves, we focus on metrics such as flow coefficient (Cv) for slurry handling (e.g., Cv > 500 for large-diameter valves), response time under 2 seconds for process control, and precise closure to avoid blockages. Actuation choices include manual, electric, pneumatic, or hydraulic systems to match your operational setup, with IP65-rated enclosures for dust and water protection in plant environments.

Tailored Solutions for Phosphate Challenges

Phosphate plants face specific hurdles:

Corrosion and Abrasion: Our premium Hastelloy C-276 or internal-lined valves combat the aggressive nature of phosphoric acid and slurries, achieving corrosion resistance up to 98% in high-concentration acids.

Pressure and Temperature Endurance: Rigorous testing ensures our valves handle digestion and filtration stresses, such as 12 bar at 90°C without deformation.

Solids Management: Engineered to prevent clogging in high-solids transport, e.g., handling 20-30% solids content in pipelines.

Maintenance Simplicity: Quick disassembly reduces operational interruptions, with modular designs for on-site repairs.

Custom Engineering: Adapted for unique plant layouts and connections, including flanged ends per ANSI B16.5 standards.

Testing Protocols

WELKIN employs thorough testing to validate valve performance: corrosion in acidic conditions, abrasion from slurries (ASTM G65), pressure integrity up to 1.5 times rated (ASME B16.34), shock resistance (MIL-STD-810), and real-world field trials in phosphate facilities.

Partnership

Partner with WELKIN for innovative valve solutions that meet phosphate processing demands. Contact us at [info@welkinenergy.com] to optimize your setup with our expert guidance